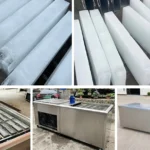

An industrial freeze dryer is an essential piece of equipment for preserving the quality, nutrition, and shelf life of a wide range of products. Our industrial freeze dryers offer batch capacities ranging from 10kg to 2000kg per run—ideal for businesses scaling up production.

Parameters of Our Industrial Freeze Dryers for Sale

| Model | Effective Area (m²) | Capacity for Raw Material (kg) | Main Dimensions (m) L×W×H | Heating Method | Total Power (kW) |

| FLDG-0.5 | 0.5 | 5 | 2.0×1.2×1.4 | Steam / Electric | 4.2 |

| FLDG-5 | 5 | 50 | 5.4×1.5×2.2 | Steam / Electric | 18.5 |

| FLDG-10 | 10 | 100 | 5.9×1.7×2.1 | Steam / Electric | 30.5 |

| FLDG-20 | 20 | 200 | 6.2×2.2×2.8 | Steam / Electric | 55 |

| FLDG-30 | 30 | 300 | 6.5×2.5×2.9 | Steam / Electric | 69.5 |

| FLDG-100 | 100 | 1000 | 11.5×2.8×3.3 | Steam / Electric | 220 |

| FLDG-200 | 200 | 2000 | 20.5×2.9×3.6 | Steam / Electric | 350 |

Industrial Vacuum Freeze Dryer Working Principle and Applications

An industrial vacuum freeze dryer (or lyophilizer) uses sublimation to remove moisture from materials—converting frozen ice directly to vapor under deep vacuum. Its process has three stages: freezing the material below its triple point, primary drying (reducing pressure to turn ice into vapor), and secondary drying (removing residual unfrozen water via desorption). Key components include a drying chamber, condenser, vacuum pump, refrigeration system, and control panel. It preserves nutrients, enables quick rehydration, and extends shelf life—making it ideal for high-value, long-storage products.

Key Features of Industrial Vacuum Freeze Drying Machines

Low-Temp Preservation

Low-temperature drying avoids heat damage, retaining 99% of nutrients in food and biological activity. Meanwhile, removing over 95% of moisture inhibits microbial growth, enabling products to last for years at room temperature without preservatives.

Rehydratable & Portable Products

Freeze-dried items (e.g., fruits, instant coffee) have a porous structure—add water to restore their original form. They also shrink to 1/5–1/10 of their original weight, perfect for outdoor use, aerospace rations, and low-cost shipping.

Durable Build

The entire drying chamber, shelves, and vapor condenser are made of SUS304 stainless steel. This ensures corrosion resistance, meets hygiene standards for food processing, and guarantees long-term durability.

High Customization

Our freeze dryer models range from a small pilot freeze dryer for lab research to a 2000kg-capacity large industrial freeze dryer. Options include steam/electric heating and automatic control.

Advantages of Our Industrial Freeze Dryer Machines

High Added Value: Freeze-dried products (like premium coffee or organic snacks) command higher prices than traditionally dried goods.

Wide Application: Our vacuum freeze dryers work for almost any material—food, pets, medicine, flowers, even cannabis (where legal).

Cost Efficiency: Each freeze dryer offers both manual and automatic system options. The automatic freeze dryers reduce labor and operational costs while also consuming less energy.

Market Demand: Consumers increasingly want healthy, preservative-free products. The high-volume freeze-dried products produced by industrial freeze dryers perfectly align with this trend.

FAQ:

Q1. What’s the difference between an industrial and a home freeze dryer?

Industrial models have larger capacities (10kg+ per batch) and heavy-duty components. Home units are smaller (4-6L) and less powerful.

Q2. How long does a batch of industrial freeze dryers take to dry?

It depends on the material and model—usually 8 to 24 hours. Larger batches may take longer.

Q3. Do I need special training to operate feeze dryer?

No. Automatic freeze dryers use PLC/HMI control panels. Most come with pre-programmed settings for common products.

Q4. Where can a vacuum freeze dryer be used?

Yes! Our vacuum freeze drying machines are critical for food processing: making instant coffee, freeze-dried fruits/veggies, pet treats & emergency rations. Retains 95%+ nutrients/flavors.

Why Choose Foodline Machinery

Foodline Machinery is a machinery manufacturing company integrating public and trade, and has a development history of more than 20 years, specializing in the production of machinery. We offer comprehensive after-sales services, including technical support, maintenance guidance, and customization options to meet specific customer requirements. With a global customer base and a reputation for excellence, we strive to be your trusted partner in nut processing, helping you improve productivity and product quality while reducing operational costs. If you’re looking for a profitable and low-maintenance commercial solution, our industrial freeze dryers for sale are the perfect choice. Fill out the inquiry form today, and our team will send you a customized quote and video demo within 24 hours.