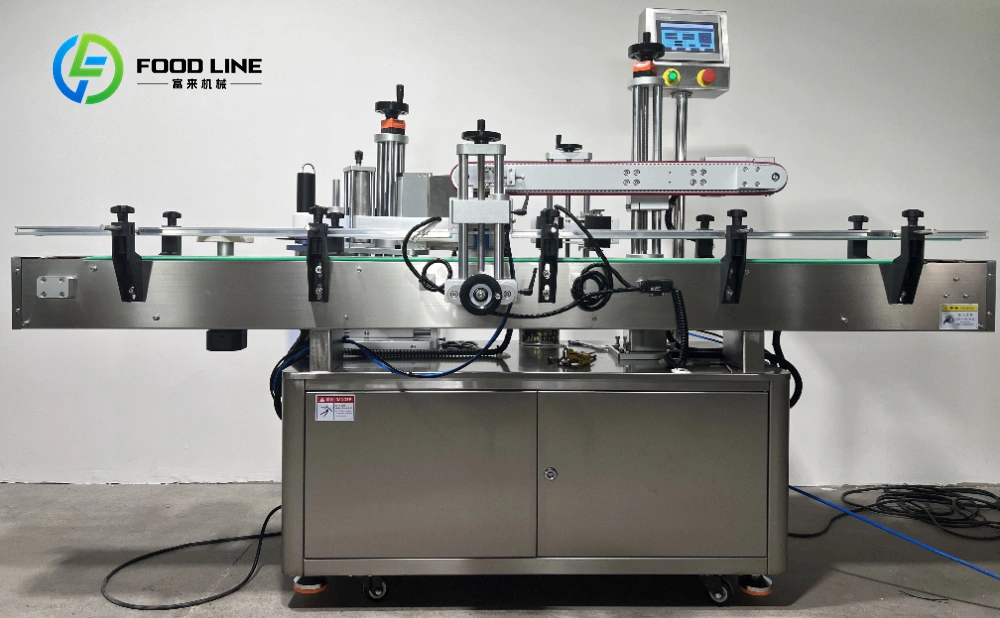

An automatic bottle labeling machine streamlines production by applying labels precisely with minimal manual effort. This versatile equipment handles both round and conical containers—including wine bottles, beverage bottles, jars, and cans. It is ideal for industries such as food & beverage, pharmaceuticals, cosmetics, and daily chemicals, helping businesses enhance efficiency and ensure consistent, high-quality labeling.

Specifications of Automatic Bottle Labeling Machine

| Parameter | Details |

| Product Model | FL-260 Round Bottle Label Machine |

| Labeling Accuracy | ±1mm |

| Labeling Speed | 15–40pcs/min |

| Power Supply | 220V/50HZ |

| Power | 1.0kw/1.5kw |

| Label Size | Length: 15mm–300mm; Width: 25mm–160mm |

| Product Size (Bottles) | Diameter: 25mm–120mm; Height: 25mm–230mm |

How Does The Automatic Bottle Labeling Machine Work?

The workflow of this automatic sticker applicator is simple and efficient:

1. First, containers (e.g., round bottles or tapered jars) are conveyed to the labeling station via a production line.

2. Then, the automatic labeling machine precisely positions the bottle (critical for fixed-point labeling).

3. Next, the automatic label applicator machine applies the sticker label to the bottle’s surface (supporting circumferential, front-back, or fixed-point labeling).

4. After that, the labeled container is sent out for subsequent production steps.

The entire process runs automatically, ensuring consistent precision and speed.

Key Features Of Automatic Label Applicator Machine

Versatile Container Compatibility

This automatic label applicator works for both standing round bottles and tapered (conical) containers – making it a practical round bottle label machine and automatic jar labeling machine (suitable for plastic, glass, or metal vessels).

Multiple Labeling Modes

The automatic bottle labeler supports 3 main labeling methods: circumferential labeling, front-back labeling for round bottles, and circumferential fixed-point labeling.

Wide Label Adaptability

It is compatible with various label types (self-adhesive labels, adhesive film, electronic monitoring codes, bar codes) with flexible size ranges (length: 15mm–300mm; width: 25mm–160mm).

Easy Operation & Adjustment

This bottle label machine switches between different bottle types or labeling modes, requiring only simple, convenient adjustments – reducing downtime between production batches.

Advantages of Automatic Label Applicator For Bottles

High Labeling Quality & Precision

The automatic bottle label applicator delivers ±1mm labeling accuracy with no bubbles, ensuring neat, professional-looking labels for every product.

Productivity Boost

With a speed of 15–40 pieces per minute, this automated labeling machine replaces manual labeling work, cutting labor time and increasing overall production output.

Seamless Production Line Integration

This automatic label applicator for bottles can be fully integrated into existing production lines, enabling simultaneous labeling during continuous manufacturing.

Robust & Reliable Design

Built with synchronized components and a user-friendly control panel, this machine offers stable, long-term operation with minimal maintenance needs.

Broad Industry Application

The automatic labeling machine serves a wide range of sectors: food & beverage, medicine, cosmetics, daily chemicals, electronics, hardware, and plastics.

FAQs of Automatic Labeling Machines

It works for standing round bottles and tapered (conical) bottles/jars (including plastic, glass, and metal vessels) – ideal as an automatic jar labeling machine.

It accommodates labels with lengths of 15mm–300mm and widths of 25mm–160mm.

Its labeling speed ranges from 15 to 40 pieces per minute, balancing efficiency and labeling precision.

Yes – this automatic label applicator machine enables the full integration into production lines, fitting seamlessly into your existing workflow.

It is widely used in the food & beverage, medicine, cosmetics, daily chemicals, electronics, hardware, and plastics industries.

About Foodmax Machines

Foodmax Machines, also known as Foodline Machinery, is a trusted food processing equipment manufacturer. We specialize in providing food processing equipment, including hot sauce bottle filling machines, bubble washing machines, bottle capping machines, and complete solutions for hot sauce production lines. Our equipment ensures stable production and quality for global food processors. With a global customer base and a reputation for excellence, we strive to be your trusted partner in food processing, helping you improve productivity and product quality while reducing operational costs.