A commercial tofu making equipment automates the entire process of tofu production, ensuring high efficiency, consistent quality, and superior hygiene. Modern tofu making machines are versatile, allowing you to produce various soybean products like firm tofu, tender tofu, tofu skin, and soy milk from one system. And our range of soy milk and tofu making machines is designed to cater to various production scales.

Product Parameters of Foodline Tofu Making Machine

| Specification | FL-300 Model | FL-200 Model | FL-100 Model | FL-60 Model |

| Voltage | 220/380V | 220/380V | 220V | 220V |

| Grinding Power | 1.5 KW | 1.5 KW | 1.1 KW | 1.1 KW |

| Cooking Power | 24 KW | 12 KW | 12 KW | 12 KW |

| Total Power | 25.65 KW | 13.65 KW | 13.1 KW | 13.1 KW |

| Dimensions (mm) | 1750 * 850 * 1300 | 1150 * 900 * 1270 | 1000 * 855 * 1350 | 1585 * 855 * 1350 |

| Soy Milk Output | 300 kg/h | 200 kg/h | 100 kg/h | 60 kg/h |

| Tofu Output | 150 kg/h | 100 kg/h | 50 kg/h | 30 kg/h |

| Molding Method | Pneumatic | Pneumatic | Pneumatic/Manual | Manual |

How Does an Automatic Tofu Making Machine Work?

The process in a soy milk and tofu making machine is streamlined and efficient. It typically involves four integrated parts to ensure a smooth workflow from raw beans to finished tofu.

1. Grinding: The operator feeds soaked soybeans into the grinding machine. This part has a built-in bean dregs separator that automatically filters the soybean milk from the okara (pulp), and eliminates the need for a separate filter.

2. Slurry Holding: The fresh soy milk flows directly into a stainless steel slurry tank, ready for the next step.

3. Cooking: The milk is then transferred to the boiler. Our equipment features double-valve control for continuous, uninterrupted boiling at precise temperatures.

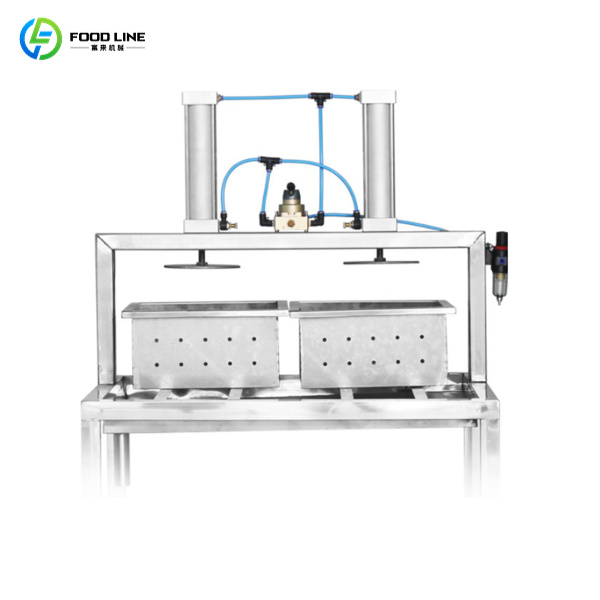

4. Forming: The cooked soy milk is coagulated and then transferred to the forming machine. Depending on the model, pneumatic or manual pressing shapes the tofu into blocks with consistent texture and density.

This entire process in a soya tofu making machine takes approximately 30 minutes, significantly faster than traditional methods.

Key Features of Our Tofu Manufacturing Equipment

One Machine, Multi-Purpose: This tofu making machine can produce a wide range of products, including monochrome tofu (tender or firm), colorful vegetable-tofu, tofu skin, and fresh soy milk.

Automatic Control System: The tofu process is fully automated with a digital temperature controller. And you can set parameters for different products

Hygienic 304 Stainless Steel: Constructed entirely from food-grade stainless steel that meets national hygiene standards. The smooth surfaces are easy to clean, and the process is designed for water-free floor operations.

Closed Ultra-High-Temperature Steam Heating: This technology heats the soy milk to over 100°C in a closed system. It eliminates harmful bacteria and the “beany” odor while preserving the soybean’s natural nutrients, color, and flavor.

Advanced Pulp Separator and Boiler: We use the most efficient components on the market to ensure a higher soybean extraction rate and more product from your raw materials.

Advantages of Commercial Tofu Making Equipment

Superior Nutrient Retention: The closed-steam heating technology prevents protein destruction, resulting in tofu that is not only tastier but also more nutritious, with a longer shelf life.

High Production Rate & Yield: The machine combines advanced grinding, separating, and cooking technologies. Thus, it helps you maximize your output, also boosting your profitability.

Substantial Energy Savings: Compared to traditional open cooking pots, our tofu manufacturing machine is over 20% more energy-efficient, reducing your operational costs.

Remarkable Convenience and Speed: With the compact and integrated design, the equipment ensures one operator to manage the entire process from raw material to finished product in just 30 minutes.

Low Operational Cost: The durable stainless steel build ensures a long lifespan. Its small footprint, easy installation, and labor-saving operation translate to an excellent return on investment.

FAQs of Tofu Machines For Sale

Our commercial tofu making equipment offers flexibility. You can choose between electric and gas heating methods based on your local utility convenience and cost.

We provide solutions for every business size. Our tofu making equipment includes small, medium, and large production line models, with capacities ranging from 30kg to over 200kg of tofu per hour.

The efficiency is high. Typically, for every 1 kg of soybeans you use, you can expect approximately 5 kg of high-quality tofu output from our soya tofu making machine.

The tofu forming machine comes in two types: a manual press and a pneumatic press. The pneumatic model uses air pressure for adjustable, consistent, and effortless pressing.

Absolutely. After purchasing, we supply detailed manuals, operation videos, and proven tofu recipes to ensure you can start production successfully and quickly.

About Foodmax Machines

Foodline Machinery (Foodmax Machinery) is a professional food trailer manufacturer with 20 years of industry expertise. We offer high-quality food processing equipment, including tofu making equipment, sugar coating machines, tapioca pearl machines, twin screw extruder machines, and more food machinery. We focus on reliability, efficiency, and customer satisfaction, with products sold to over 30 countries worldwide, including the USA, Japan, the Philippines, India, Malaysia, and many Middle Eastern countries. If you’re looking for a reliable and profitable food processing solution, please feel free to ask for a quote.